Research

Keyword

- Chemical Engineering

- Suspension Rheology

- Powder Technology

Experiments on dispersion and aggregation behavior of fine particles

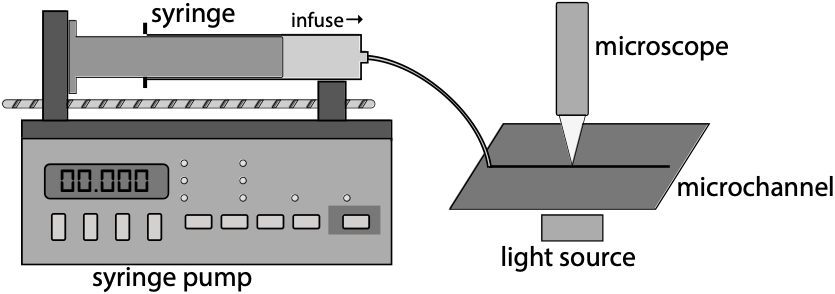

We conduct experiments on the aggregation and dispersion of fine particles in shear and extensional flows. Small particles are known to adhere to each other and form clusters in suspension, and by studying how these clusters break down, we contribute to the polymer composite manufacturing process.

Microchannel apparatus for observation of dispersion and aggregation behavior.

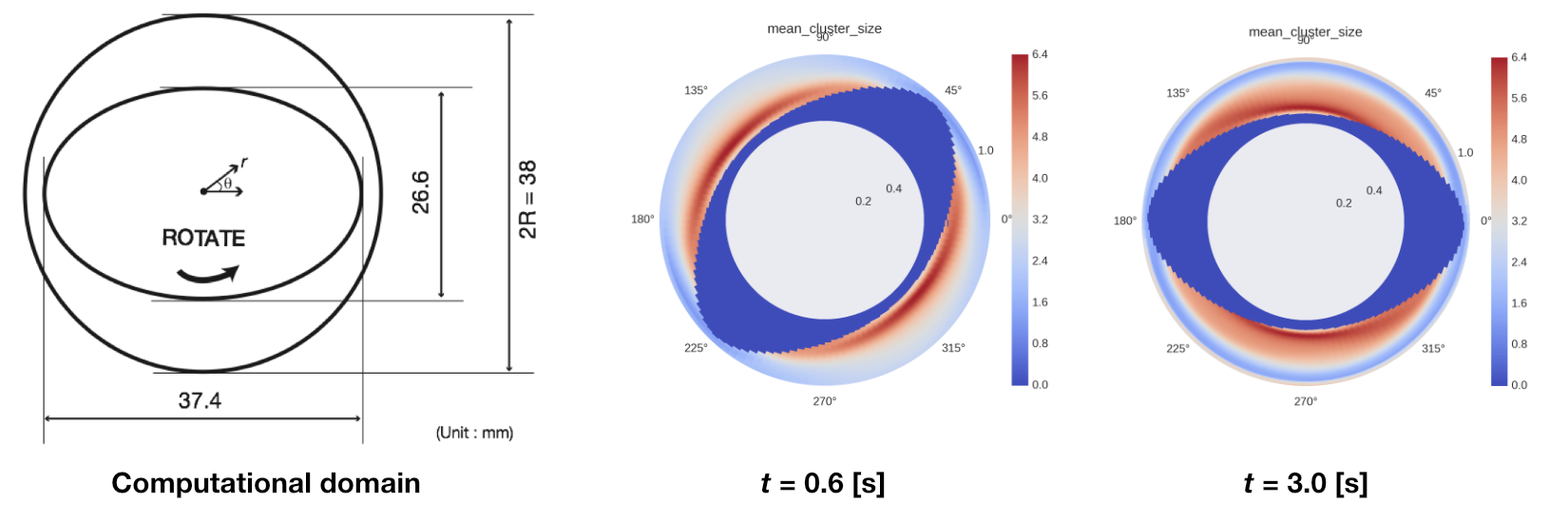

Numerical calculations of dispersion and aggregation behavior of fine particles

By calculating the formation and disappearance rates of clusters, we perform numerical calculations of the dispersion and aggregation behavior of fine particles. We study, in addition, how clusters break up in a uniaxial mixer by combining with CFD calculations.

Computational domain for calculation and the time variation of mean cluster size.

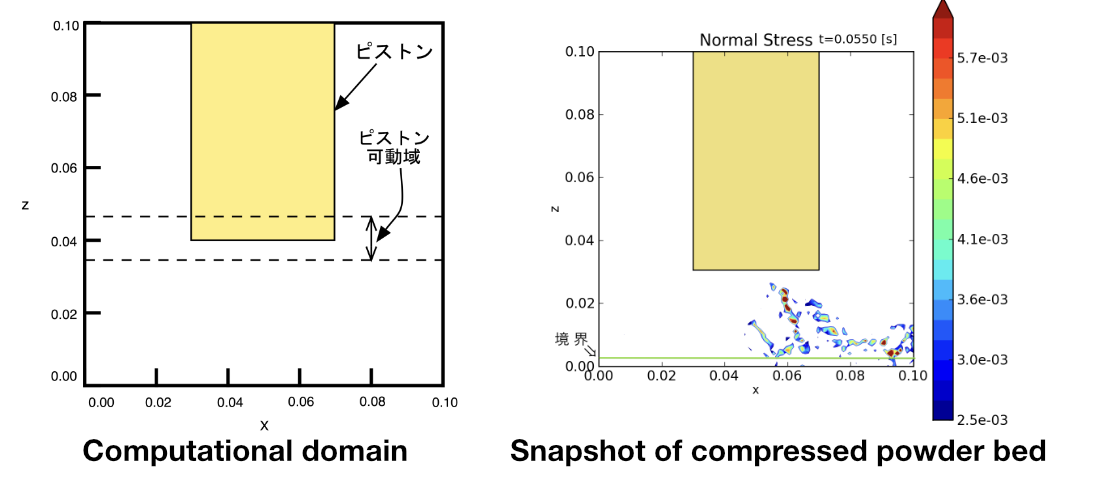

Numerical calculation of normal stress distribution in a two-layered powder bed

When powders come into contact with each other or are strongly compacted, a jamming transition occurs, which reduces the fluidity of the powder. By numerically calculating the distribution of normal stresses when compressing a two-layered powder bed of particles of different sizes, it is possible to use this information in processes using powders.

Computational domain for calculation and the snapshot of the powder bed compressed by a moving piston.

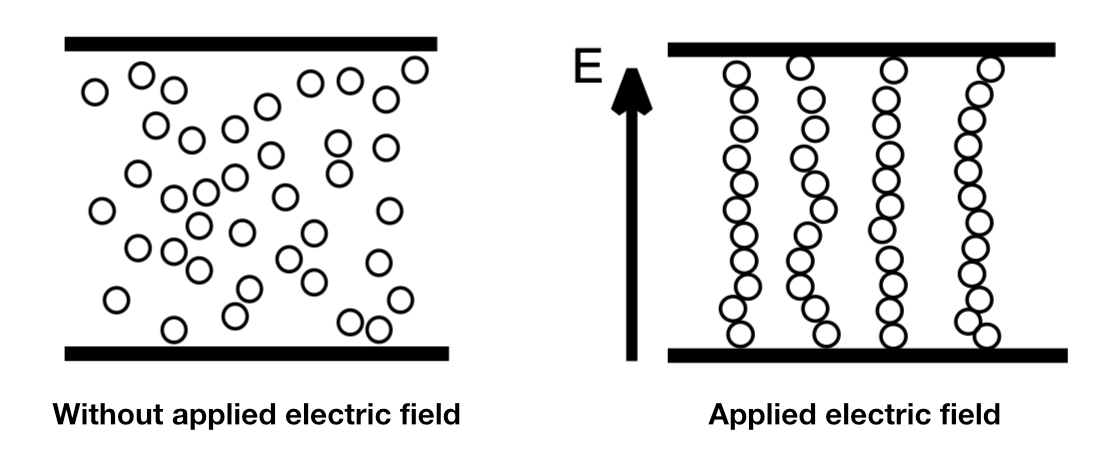

Research on the internal structure of dispersed electrorheological suspension

We research on dispersed ER fluids in collaboration with the Minami Laboratory of the Department of Electrical Engineering. Our research aims to evaluate the internal structure of dispersed ER liquids by measuring the microcurrents flowing through them that change their internal structure when an electric field is applied.

The inner structure of electrorheological suspension along an electric field.

Powder research in a universal gripper

We research on universal gripping in cooperation with the Shimizu Laboratory of the Department of Mechanical Engineering. We are heat-treating the powder inside the universal grip and studying how the strength changes when the surface shape changes.